Subsea Robotic Umbilical Cable

Subsea ROV Umbilical Cables

Highly Integrated & Customized Solutions

ROV umbilical cables embody a composite cable design, integrating multiple functional units into a single, robust assembly for complex underwater operations.

Core Design Philosophy: High Integration & Customization

Power Transmission: Integrated power cores deliver ample electricity to the ROV's thrusters, manipulators, lights, and other systems.

Signal & Control: Contains dedicated signal/control cores for transmitting sensor data, commands, and control signals, ensuring the operator's precise maneuverability and control over the ROV.

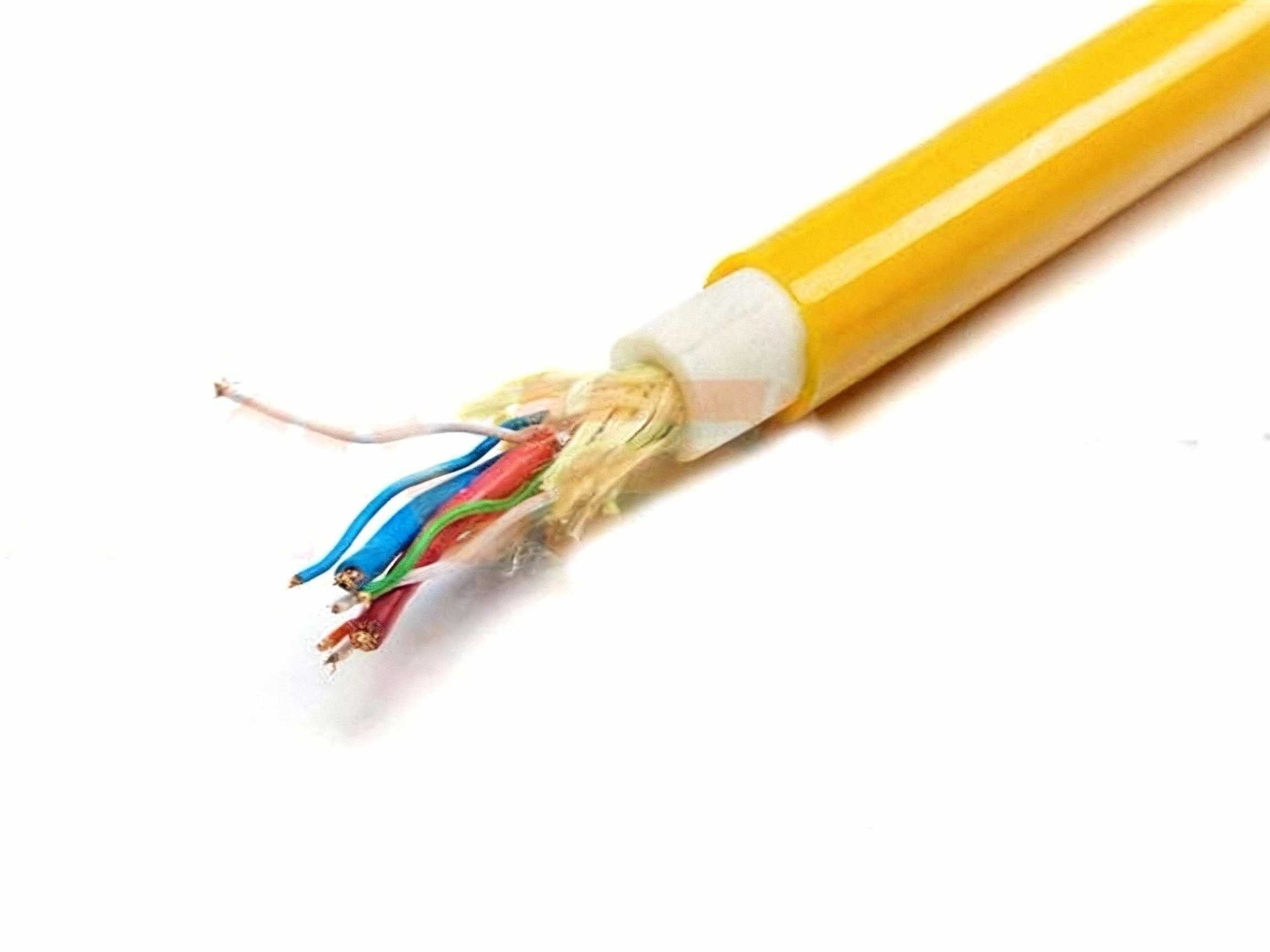

Video/Data Communication: Integrated coaxial cables or, critically, fiber optics enable high-definition video and high-speed data transmission over long distances with superior bandwidth and EMI immunity.

Customized Integration: We create hybrid electro-optical cables by combining single-mode/multi-mode fibers with power cores, meeting simultaneous demands for power and ultra-high bandwidth.

Key Performance Parameters & Customization Range

Tensile Strength: Customizable from 0 to 6 tonnes. Enhanced Kevlar fiber content and advanced braiding techniques achieve high strength for deep-water applications and strong currents.

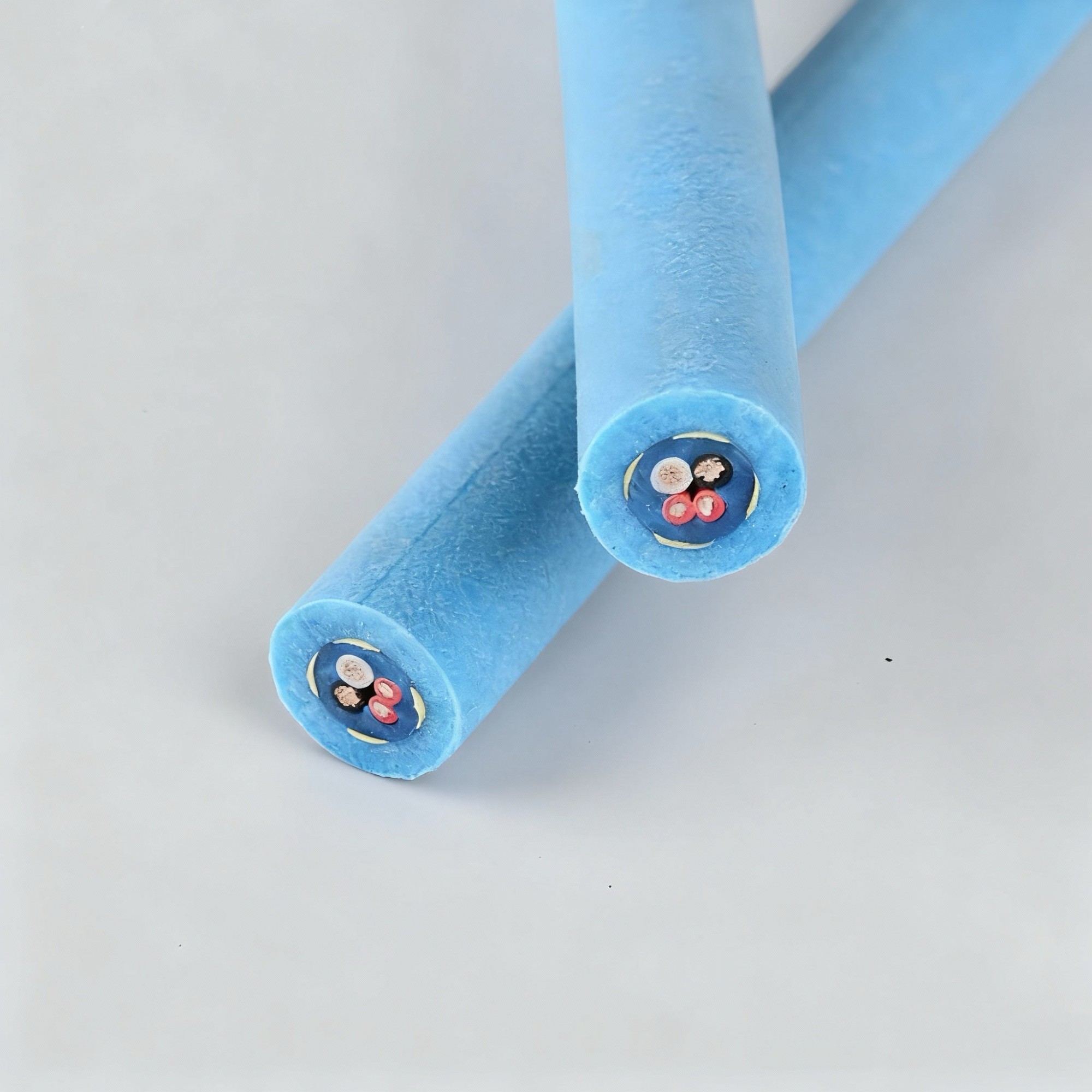

Neutral Buoyancy / Zero Buoyancy: Achieved via specialized foamed sheathing materials and construction, minimizing cable weight impact on ROV stability and maneuverability.

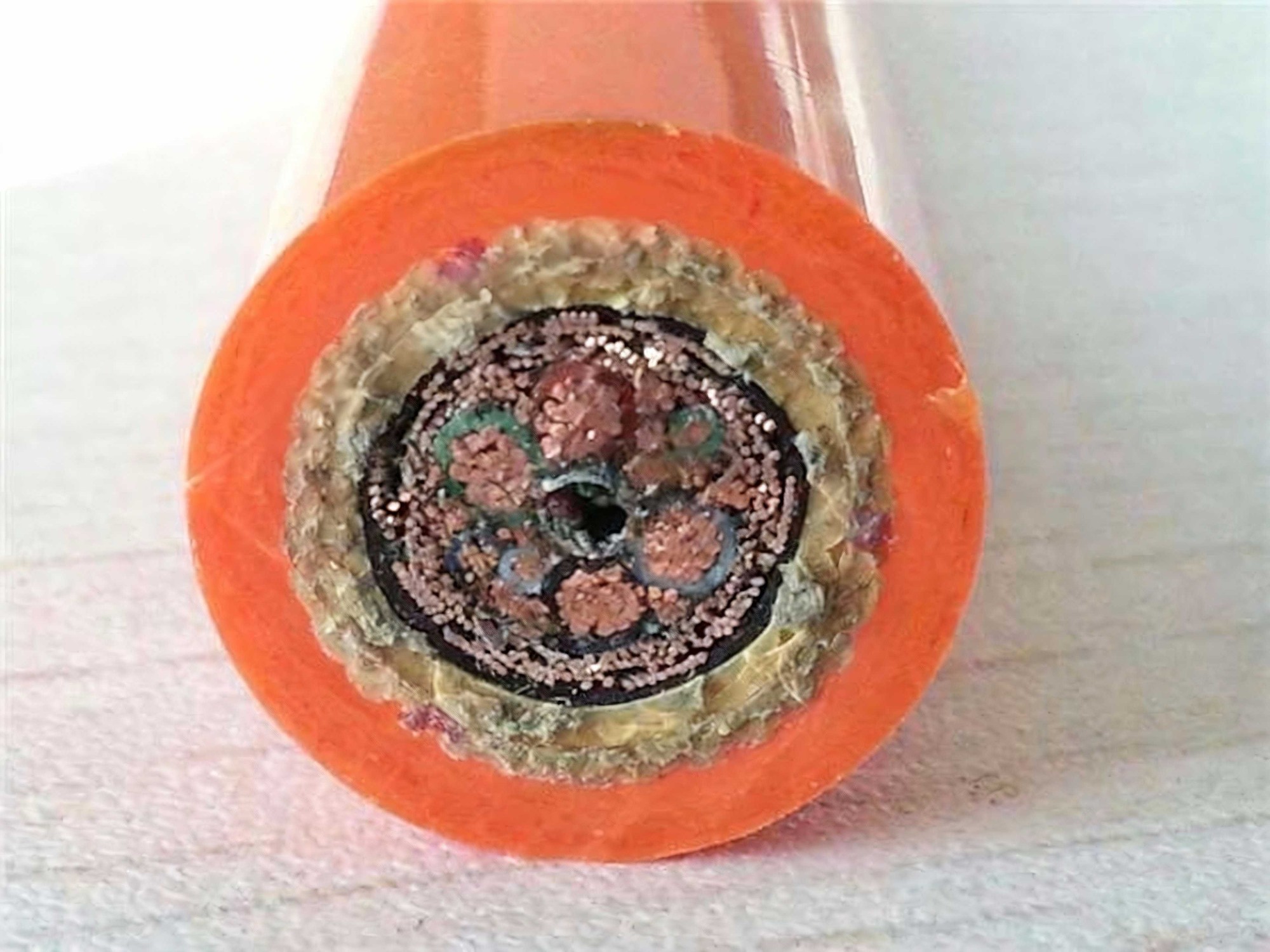

Cable Specification: Extensive range from 1 to 60 cores, with conductor cross-sections from 0.08 mm² to 35 mm², catering to various ROVs from micro observation classes to large work-class ROVs.

Custom Length: Supplied cut-to-length for easy deployment and use.

Detailed Construction and Material Analysis

Conductor

Material: Fine-stranded, extra-flexible tinned soft copper wire.

Insulation

Material: Materials like Foamed TPE, TPE, TPV, XLPE, DPEM

Core Structure

Process: Features anti-twist layering, grouped gap filling, twisted pairs, and layered binding to optimize stress distribution, prevent internal movement, and ensure structural stability and signal integrity.

Shielding

Individual Pair/Group Shielding: Protects sensitive signal lines (e.g., twisted pairs) from crosstalk.

Overall Shield : A combination of tinned copper braid provides 360° EMI/RFI shielding against external interference.

Tensile Strength Member

Central Kevlar Core: Serves as the primary load-bearing element.

Interstitial Kevlar Fill: Fills voids within the cable core.

Kevlar Braid: One or more braided layers surrounding the core.

Sheath / Jacket

Inner Sheath: Low-viscosity, high-strength extrusion tightly binds components, forming a primary barrier.

Outer Sheath: Abrasion-resistant Polyurethane (PU).

Application

Remotely Operated Vehicles (ROVs)

Underwater Camera & Monitoring Systems

Submarines & Naval Vessels

Underwater Survey & Exploration

Marine Science & Research

Underwater Engineering & Construction