Subsea Hybrid Electro-Optical Cables

Exploring the Deep, Connecting the Future

Beneath the ocean's depths, reliable data and power transmission are the unseen lifelines of our interconnected world. We deliver next-generation Subsea Hybrid Electro-Optical Cables, seamlessly merging high-capacity power transmission with ultra-high-speed fiber optic communication in one integrated solution—powering the future of marine energy, scientific discovery, and global connectivity.

Unified Design, Dual Mission

Our hybrid cable integrates two essential functions into one robust core:

Power Unit: Delivers medium/high-voltage electricity to energize offshore systems and subsea networks.

Fiber Optic Unit: Enables high-speed, low-latency data transmission for real-time monitoring, HD video, and scientific communication.

Core Advantages

High Reliability: Built with multi-layer armor to endure extreme deep-sea conditions.

Exceptional Performance: Combines stable, low-loss fiber optics with efficient power conductors for reliable data and energy delivery.

System Simplification: One cable for both power and data streamlines installation and cuts lifecycle costs.

Flexible Customization: Tailored to your needs—from offshore wind farms to seabed observatories—in voltage, fiber count, armor, and length.

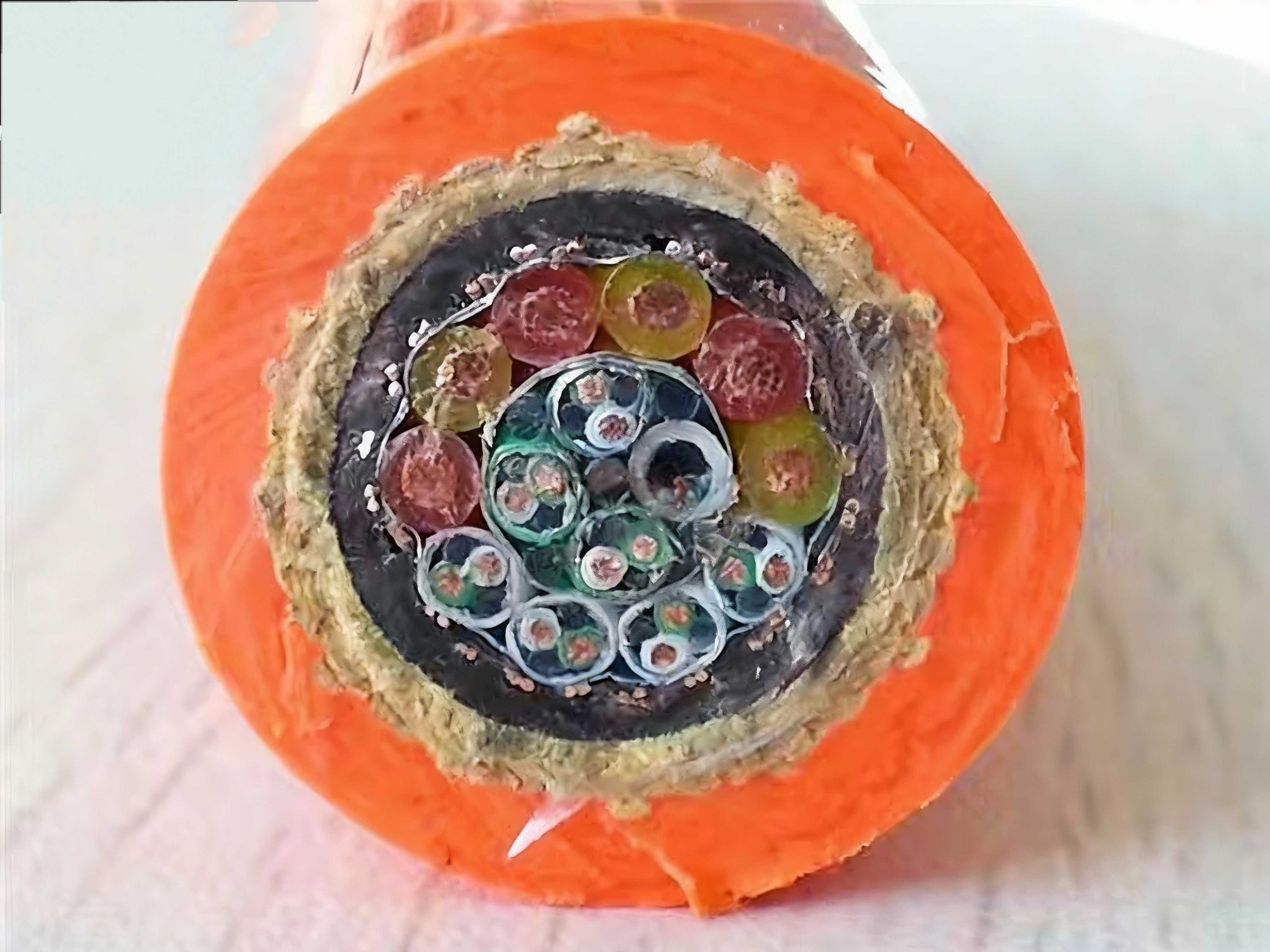

Detailed Construction and Material Analysis

Conductor

Material: Finely stranded and bunch-stranded, extra-fine oxygen-free copper wires / Anti-corrosion tinned copper wires. Customizable per requirement.

Cross-Section: Customized per customer specifications.

Structure: Anti-twist layered construction; grouped interstitial filling; pairs are first twisted, then layered and bundled.

Insulation

Material: Seawater-resistant compounded PVC / Corrosion-resistant Teflon (PTFE) plastic; specially formulated foamed thermoplastic elastomer / TPV / TPE. Customizable per requirement.

Color Coding:

For conductors ≤ 0.5 mm²: Color-coded (brown, black, blue, purple, pink, orange).

For conductors > 0.5 mm²: Black insulation with white numbering.

Cables with 3 or more cores include a yellow/green ground wire.

Water-Blocking Structure

Water-blocking compound filling.

Tensile Strength Member

Polyester yarn fiber / High-strength, tensile aramid fiber (e.g., Kevlar) / Optional finely stranded steel wires.

Inner Sheath

Modified low-viscosity, high-compression inner sheath. Optional based on environmental requirements.

Screening / Shield

Braided tinned copper screen with a density ≥ 85%.

Lay-Up Structure

Anti-twist layered construction; grouped interstitial filling; pairs are first twisted, then layered and bundled.

Outer Sheath (Jacket)

Material: Imported TPU compound or polyurethane (PUR) that is seawater-proof, water-resistant, acid/alkali-resistant, UV-resistant, and corrosion-resistant. Available in various colors, customizable.

Applications

Marine Renewable Energy: Connects and powers offshore wind, wave, and tidal energy systems.

Oil & Gas Production: Provides power and control for subsea infrastructure.

Scientific Networks: Supports seabed observatories with continuous power and data transmission.

Island Interconnection: Delivers both electricity and high-speed communication to remote islands.