Cryogenic & Low-Temp Cable Solutions

Low-Temperature Cables | Cryogenic Cables | Flexible Cold-Resistant Cable Solutions

In industrial and technological sectors, the reliable operation of critical applications—from cryogenic systems and arctic outdoor installations to automated logistics and special equipment—is fundamentally dependent on cable connections that maintain their physical and electrical integrity under low-temperature and extreme-cold conditions.

Our series of Low-Temperature Cables are engineered through advanced polymer science, utilizing specialized elastomer compounds and optimized construction. The core objective is to ensure that our cables retain exceptional flexibility, mechanical strength, and reliable electrical insulation even under specified extreme cold conditions. We provide durable and stable solutions for power transmission and signal control in the most demanding environments.

| Feature | Ultra Deep Cryogenic Cable (-200°C) | Deep Freeze Resistant Cable (-60°C) | Standard Low-Temperature Cable (-45°C) | Low-Temperature Crane & Drag Cable |

Min. Temperature Rating | -200℃ | -60°C | -45°C | -60°C / -45°C (Options) |

| Applications | Cryogenic systems, LNG transfer, superconducting research, aerospace testing | Freezer plants, arctic outdoor equipment, cold storage applications | General low-temperature industrial automation, chilled environments | Port cranes, gantry cranes, hoists, automated warehousing |

| Characteristics | Superior flexibility at cryogenic temperatures, resistant to cracking | Excellent cold resistance, oil-resistant, durable | Cost-effective low-temperature flexibility, reliable performance | High flexibility, abrasion-resistant, UV resistant, tear-resistant |

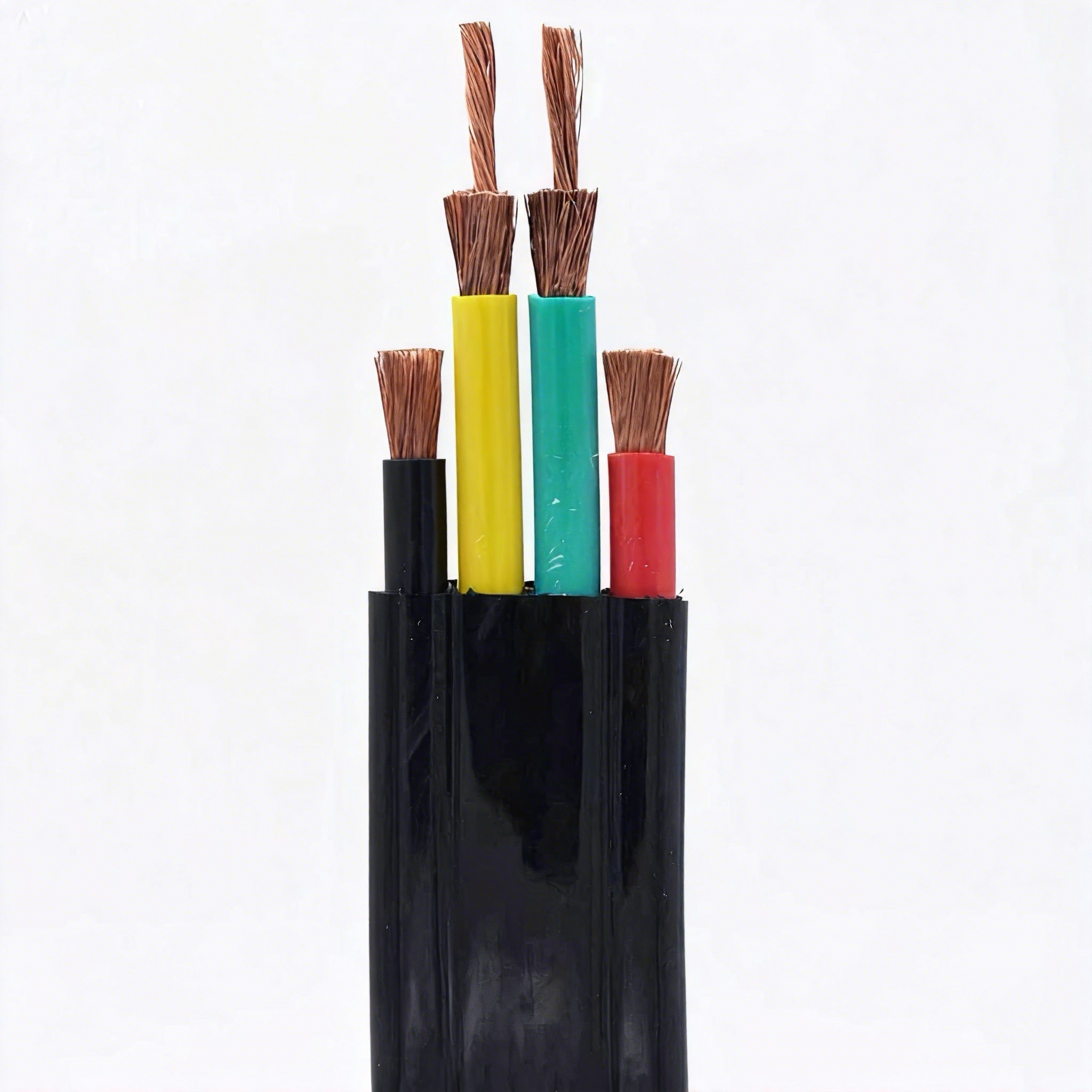

| Conductor | Fine bare copper | Fine bare copper | Bare copper | Extra-fine bare copper (multi-stranded) |

Insulation /Sheath | Specialty Elastomer / PUR | Premium PVC / Elastomer blend | Low-Temperature PVC / Elastomer | Reinforced PUR Sheath or CPE |

| Flexibility | Exceptional | Very Good | Good | Exceptional (for continuous movement) |

Additional Features | Resists coolants and liquefied gases | Good chemical and oil resistance | General purpose | Integrated anti-twist elements, high tensile strength |

Core Advantages

Reinforced Cable Construction: Typically incorporates a central core of aramid fiber or galvanized steel wire rope as a tensile strength member to withstand mechanical pulling forces.

Exceptional Cable Flexibility: Conductors are finely stranded with extra-flexible bare copper, and the sheath utilizes high-elasticity PUR material, enabling the cable to withstand millions of continuous flexing cycles.

Comprehensive Cable Protection: Offers excellent resistance to oil, abrasion, and UV radiation (for outdoor applications), ensuring all-around durability.

Applications

Gantry cranes and overhead bridge cranes in workshops

Automated storage and retrieval systems (AS/RS) and stacker cranes

Any heavy-duty equipment requiring mobile power supply solutions